10 Manufacturing skills for today's industry

The manufacturing industry rapidly changes to respond to markets, supplies, and environmental factors. The key to success is for organizations to maintain adaptability across all segments, requiring well-skilled employees.

We’re here to explore the diverse manufacturing skills teams need to stand out among many customer choices. We’ll discuss the value of each skill in enhancing production effectiveness and meeting industry standards.

What is a manufacturing skill?

Manufacturing skills are the abilities that allow workers to perform their production roles effectively and adapt to the industry's evolving demands. Whether technical, industrial, or analytical, these skills form the foundation for maintaining efficient production processes that meet customer needs.

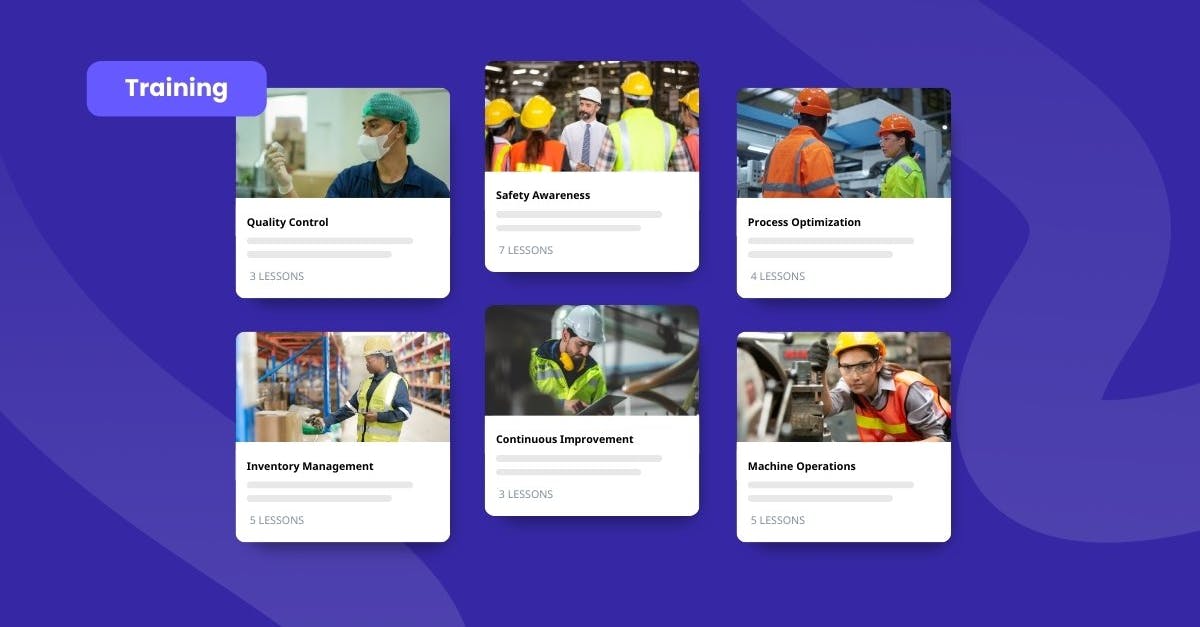

10 Essential manufacturing skills

Let’s explore key manufacturing skills examples that are crucial to a production business’s efficiency and profitability.

1. Quality control

Production skills related to quality control (QC) help your team identify defects as early as possible in the lifecycle. This minimizes waste and scrap from errors while correcting them to meet specifications.

QC skills involve the technical and analytical parts of quality assurance processes. Control expertise includes metric analysis, output assessment, and measurement tools to make sure products reach predetermined standards.

In practice, quality control skills are handy for tasks such as:

- Statistical process control analysis

- Product audits

- In-process inspections

- Raw material testing

2. Continuous improvement

Continuous improvement encompasses a set of skills that equip employees to identify and implement production changes for long-term benefits. Transformational initiative examples are accelerating workflows, eliminating unnecessary processes, and condensing material flow paths.

Your teams will need manufacturing training to improve continuously. Their skills and knowledge must be regularly updated, sharpening their work.

Continuous improvement abilities are helpful for:

- Standardizing processes

- Eliminating bottlenecks

- Expanding manufacturing capacity

- Reducing operational costs

3. Safety awareness

One of the most significant manufacturing industry challenges is worker safety. Fall hazards, machine pinch points, and chemical exposure remain common on work floors, calling for heightened safety awareness.

Safety skills for manufacturing cover the practical application and knowledge of protecting one’s health and well-being. Learning safety measures and techniques helps your crew to comply with regulations and follow operational procedures. As a result, your business benefits from lower absenteeism and decreased compensation costs.

Higher safety awareness is crucial for:

- Proper guarding implementation

- Safe equipment operation and maintenance

- Personal protective equipment use

- Complete inspections and audits

You can explore SC Training’s manufacturing safety course library to jumpstart safety programs.

4. Machine operations and technical machining

Mastering machine operations and technical machining lets your workers increase their task accuracy and consistency. While manual handling training is still valuable, gaining a grasp of machinery reduces physical labor by automating tedious processes.

To achieve these benefits, operators must understand the machine’s principles, functions, controls, and protocols. Additionally, they should learn how to troubleshoot and maintain equipment based on its technical specifications. With this knowledge, precise craftsmanship of parts and products can follow.

Because of this skillset, production line workers can:

- Set up and calibrate systems effectively

- Monitor quality

- Complete mills, turns, grinds, and drills efficiently

5. Digital tool expertise

Today’s production sites feature digital systems that automate, track, and monitor processes without requiring paper or handwriting. Organizations that embrace these technologies gain a competitive advantage due to their efficiency and speed.

Because of this, equipping your employees to adopt digital manufacturing tools is key to staying ahead of the curve and cultivating customer satisfaction. An LMS for manufacturing, like SC Training, trains team members to use electronic work systems, unlocking more flexible operations.

Digital tools improve manufacturing workflows with:

- Electronic checklist and audit adoption

- Smoother supply chain communication

- Manufacturing execution system (MES) and computer-aided design (CAD) software maximization

- Reliable documentation and inspections

6. Device programming

Building on our previous skillset, device programming knowledge uses modern tools and technologies to increase visibility across production. This allows your team to set up functions such as sensors, controllers, and algorithms. With these resources, managing processes, equipment, and inventory becomes easier.

This technical expertise covers programming languages for automating production controllers. The computer system helps employees govern production cycles with precision and reliability.

This complex specialization offers solutions for:

- Computerizing operations and monitoring

- Using computer numerical controls (CNCs) and robotics

- Applying Industry 5.0 principles

Considering the challenging aspects of device programming, we recommend refresher courses from SC Training, such as Computer Numerical Control (CNC) Machining.

7. Data analysis

Raw operational statistics can’t be used for meaningful business decisions without the process of data analysis. The manufacturing skill supplies your team with interpretive methods and sets that turn numbers into insightful strategies for organizational growth.

Using analytical procedures, team members can measure and predict every phase of production chains. This includes forecasts of resources, failures, and output, aiding crews to take immediate action.

Data analysis calculates the following manufacturing tasks:

- Predicting potential failures

- Benchmarking quality and identifying variations

- Projecting demand and inventory

- Suspecting bottlenecks and risks

8. Inventory management

Manufacturing skills for handling inventory consist of savvy expertise in balancing supply with demand while maintaining cost efficiency. Employees with these abilities can effectively oversee procurement, production, storage, and sales of products.

Besides that, those well-versed in inventory management can successfully account for equipment expenses, production materials, and customer purchases. This way, the business can reduce surpluses and shortages, strengthening supply chains.

Inventory management is crucial for:

- Tracking product movement and aging

- Stocking in proper amounts

- Controlling warehouse procedures

- Allocating resources across maintenance, repair, and operations (MRO) of production

9. Process optimization

Process optimization works alongside continuous improvements to enhance overall resource usage. As the skill name suggests, it focuses on the procedures that directly interact with product creation. It aids your workers in identifying process constraints and limitations.

Through these findings, they can refine processes and heighten output without increasing expenses.

Process optimization in practice includes:

- Shortening workflows

- Implementing technological solutions

- Improving workspaces

- Strengthening defect prevention methods

With SC Training’s all-in-one file briefcase storage, you can keep standard procedures within reach without using long folders.

10. Communication and documentation

Clear messaging and writing are the primary factors that dictate the seamless flow of information across a manufacturing organization. This requires open communication structures and actionable documentation methods.

When your employees know how to convey ideas and record scenarios, insights are effectively delivered and applied to solutions. This skill helps foster a better understanding of various production aspects. These can cover policies, feedback, incidents, and requirements.

Well-trained teams for communication and documentation can:

- Implement and follow process maps and flowcharts

- Deliver real-time updates, especially for QC and inventory

- Document compliance reports

- Create trackable audit trails

Produce high-performing manufacturing teams with SC Training

Every business aims to develop its workforce's abilities, however, this often requires significant time, cost, and effort. Fortunately, with SC Training, we offer a top manufacturing training solution that simplifies skill growth programs into a flexible initiative.

Training becomes effortless with our platform. Our course library features a wide range of ready-to-use manufacturing lessons, all vetted by experts to secure top-notch knowledge. And if you want to train your teams on organizational procedures and policies, our AI document converter can transform files into modules in seconds.

SC Training is more than just a course delivery software, though. It also allows you to verify and assess each worker’s training progress, all from the comfort of the app. With the practical assessment feature, you can customize digital checklists, ratings, and more, rather than relying on outdated clipboards.

The best part is that you can monitor these evaluations and course completions in one dashboard. Our Reporting and Analytics delivers real-time updates on results and performance, making auditing easy.

Need more proof? Ask Mars, Incorporated, maker of many international treats like M&Ms, about how SC Training has eased their manufacturing skills training.

Author

Mackie Angat

Mackie Angat is a content specialist at SC Training, a frontline training platform dedicated to helping businesses achieve operational excellence. He brings knowledge and insights in compliance training, industrial safety, and quality management, allowing him to create content that addresses the needs and challenges of the construction and manufacturing industries. Outside of work, Mackie enjoys working out, exploring music, and watching films.