A guide to SOP training in manufacturing

Effectively implementing standard operating procedures (SOPs) requires commitment to instructing your workers on how processes must be completed. While it can be straightforward, many aspects of training need careful planning and consideration.

In this article, we’ll take you through a general guide for delivering SOP training. We’ll discuss how to teach teams these work manuals and the topics to cover. Along the way, we’d also give practical examples on implementing these techniques and suggest tools to help you.

What is SOP training in manufacturing?

SOP training teaches manufacturing workers how to understand and follow documented task instructions exactly as written. It helps them complete procedures correctly, which is crucial in an industry that's particular about accuracy. This is valuable to processes such as equipment operations, assembly work, quality checks, and sanitization.

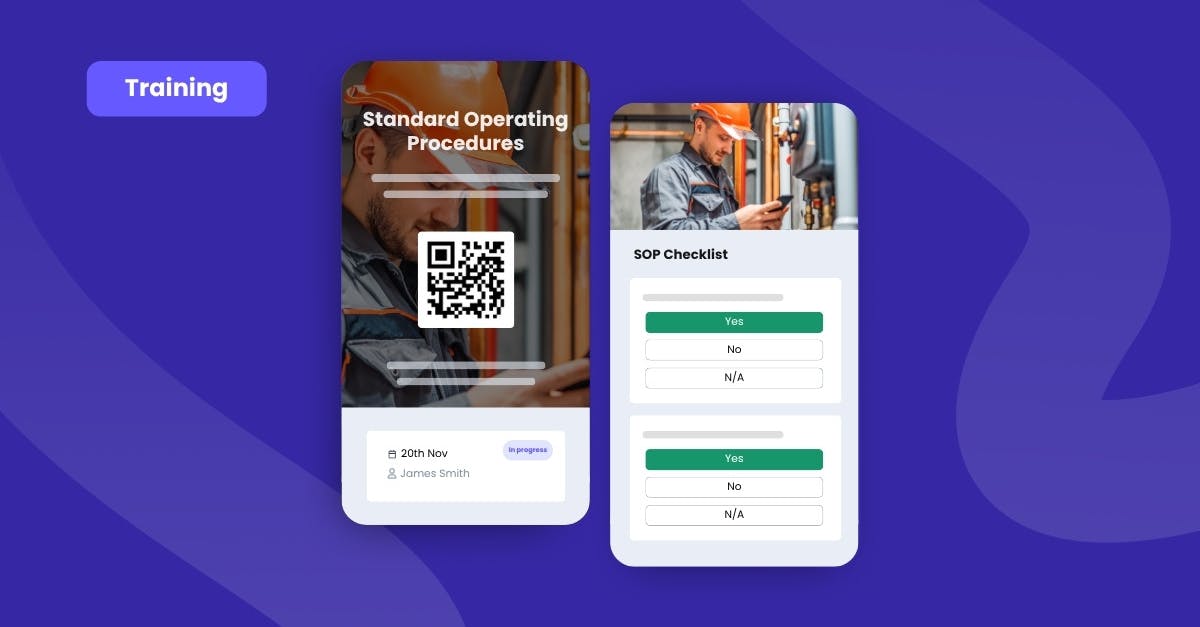

You can start training teams on SOPs as soon as you need with SC Training. The platform’s SOP training solutions allow you to deliver timely employee courses and assessments tailored to your policies and work instructions. This way, you can boost operational consistency and excellence while reducing errors.

What are the benefits of SOP training?

Delivering dedicated training about your organization’s SOPs improves operational excellence and efficiency. Let’s break that down further below:

- Faster onboarding and inductions: A dedicated course on standard procedures helps teams understand their roles immediately, resulting in quicker productivity.

- Increased consistency: Training makes sure everyone performs their tasks according to predetermined standards, which minimizes product variations.

- Stronger quality assurance: Employees who grasp each step of the production process can reduce errors and breakdowns that lead to defective output.

- Boost in productivity: When tasks are completed correctly right away, crew members can move on to other responsibilities and check off more work.

- Enhanced awareness of best practices: Teaching standard practices empowers teams to remain responsible and cautious during production.

- Secured compliance and workplace safety: Implementing work instructions through training encourages employees to adhere to regulations and apply hazard management strategies.

How can you facilitate SOP training in manufacturing

Manufacturing training on task SOPs should not be a mere read-through of the document. Crew members need exercises, in-depth discussions, and learning opportunities to grasp the importance of these guides. Through this approach, you can trust them to follow standard work practices.

Here are our recommended methods to use for your training SOP. For a comprehensive course, it’s best to mix or use all of these techniques.

Classroom discussions

Gathering your crew to discuss the job SOP offers an opportunity to guide them through every detail of the manual. During these sessions, you can:

- Elaborate on each step, outlining the rationale behind them

- Clarify any confusion and uncertainties

- Address possible scenarios where they can encounter difficulties

If you’re talking to machine operators, for example, you can use the classroom discussion to outline proper start-up, shutdown, and clean-up procedures.

Demonstrations and hands-on practice

A step-by-step demonstration of SOPs allows your workers to visualize the task process, rather than relying solely on verbal instructions. Besides seeing the procedure firsthand, this approach also reduces language barriers and accommodates varying levels of literacy.

Meanwhile, hands-on practice lets employees perform the procedure themselves as many times as necessary. This builds their mastery of the task, making best practices a habit.

In case you’re training line workers, you can use this approach to:

- Present the conveyor safety practices they must follow

- Simulate assembly, labeling, and packaging workflows

- Practice writing log forms

Multimedia modules and instructions

Adding videos, images, diagrams, eLearning courses, and other multimedia formats to SOP training templates helps crew members understand required practices. These materials can break down complex tasks and simplify them for easier learning.

For instance, you can use multimedia instructions to guide workers through the challenges and strict policies of hazardous material handling. This can work by:

- Implementing diagrams to explain the meaning of pictograms found on chemical labels

- Delivering online modules to explain each section of the safety data sheet

- Publishing videos that demonstrate dangerous spill response and disposal at critical moments

If you’re considering implementing more engaging training materials, SC Training offers powerful AI tools that do most of the work for you. They can convert SOP files into courses, translate content into the right locale, and add in-lesson narration, boosting the impact of instructional training.

On-the-job evaluations

Competency assessments allow employees to demonstrate their mastery of task procedures based on quality, safety, and regulatory requirements. In a controlled work setting, check your team member’s execution of each process step. From there, you can identify evident knowledge gaps and offer necessary feedback.

Like when training workers on equipment calibration SOPs, give them time to perform the process on their own and observe whether:

- They used reference gauges and meters for pressure and temperature properly

- Crew members make the necessary adjustments to mechanical, electrical, and firmware components

- Calibrating technicians issue certificates and reports with complete information

Implement standardization and enhance consistency in your worker evaluations with SC Training’s practical assessment tool. You can equip your team leads and training managers with a digital assessment checklist that includes the necessary fields to deliver comprehensive reviews. And it’s all in the app, no need for paper-based sheets.

What topics should be covered in SOP training?

Training manufacturing workers on their relevant SOPs must include the essential components of the document that promote excellent work. To make sure each employee performs processes the same way and with minimal errors, you should cover the following:

Purpose behind the SOP

Workers are more likely to follow the required procedures when the reasons and intended uses are explained. They’ll make sure that each measure and process stated is completed if they are aware that it will help avoid safety risks, prevent potential errors, or minimize equipment damage.

During training, clarify to your teams:

- When and where to use a certain SOP, like specifying that heavy products must be processed through a roller conveyor, as the belt is more durable and stable.

- Examples of misuses and misappropriations of an SOP, such as using reach truck checks and operational instructions on order pickers

- The problems that can be mitigated by following SOPs properly, for instance, program mismatches when operating CNC machines

Step-by-step procedures and process-specific instructions

Outlining each step of the process allows you to discuss, demonstrate, and assess every:

- Sub step

- Essential resources, tools, and materials

- Checkpoints for crucial decisions, like checking component conditions and non-conformance detection

This topic also offers an opportunity to tailor standard procedure training to address specific responsibilities, scenarios, and operations. These include:

- Multi-person tasks where each team member has their own requirements to meet, like machine tending and material handling

- SOPs for unique situations, such as job shop manufacturing for customizing products based on special customer orders

Quality control measures

Extensively training employees on the quality tests, inspections, and fixes that SOPs detail enhances the guide’s effectiveness. After all, the value of processes is determined by how much they deliver products that satisfy customer expectations and standards.

Make sure to teach them the specifications of:

- Incoming material assessments

- Instruments and metrics for dimensional inspections

- Monitoring process parameters

- Functional testing

- Visual checks

SafetyCulture’s content library includes many ready-to-use checklists to help teams get up to speed on following standard work procedures. One of which is this industry-vetted Manufacturing Quality Control Checklist. It guides your workers through key inspections and makes sure they complete general quality requirements.

Safety protocols

Taking the time to instruct your teams on essential safety protocols from operating procedures encourages careful work. When you show them how much you value their well-being, they are more likely to be cautious, addressing safety risks and reducing workplace incidents.

In your SOP for training, emphasize these safety components of the manual:

- Risk assessments

- Hazard isolations and controls

- Equipment safeguard installations, checks, and use

- Incident reporting process

Compliance requirements

Keeping employees compliant with industry standards, safety regulations, and legal requirements is one of the most significant challenges in manufacturing. A practical and efficient solution is to emphasize the processes in your guidelines that support operational adherence.

Review SOPs with your team and highlight the critical steps that follow:

- OSHA CFR 1910 for legal health and safety compliance in the US

- Health and Safety at Work Act 1974 for legal health and safety compliance in the UK

- ISO 45001:2018 for certifying occupational health and safety management systems

- ISO 9001:2015 for certifying quality management systems

- UK Conformity Assessed (UKCA) markings for safety approval of final products

- Canadian Workplace Hazardous Materials Information System (WHMIS) for hazard communication

Proper maintenance

Equipment operators are responsible for maintaining and repairing vehicles and machines. These tasks are critical to quality assurance and operational safety, which is why training on SOPs should guide workers through:

- Routine checks for lubrication, calibration, and cleaning

- Condition monitoring guidelines for parameters such as vibration, noise, and temperature

- Taking inventory of tools and spare parts

Essential documentation

Auditing trails, compliance, and quality assurance need thorough documentation. This is why your team’s awareness of logging procedures must be a priority.

Make it a point to discuss standard documentation processes, including:

- Conformity certificates

- Batch records of tasks, materials, and personnel

- Product traceability records

- Maintenance checklists

Turn standards into reality with SC Training!

Non-conformance of processes and products can significantly compromise budgets, safety, and customer satisfaction. While promoting adherence to standards amongst workers presents challenges, it should never prevent you from upholding high-quality work.

That’s where SC Training helps you thrive. It’s a reliable compliance training software that simplifies the work of instructing manufacturing teams, all while enhancing effectiveness. With the platform, you create, publish, assess, and assign training paths for employees, seamlessly equipping them to drive productivity.

Author

Mackie Angat

Mackie Angat is a content specialist at SC Training, a frontline training platform dedicated to helping businesses achieve operational excellence. He brings knowledge and insights in compliance training, industrial safety, and quality management, allowing him to create content that addresses the needs and challenges of the construction and manufacturing industries. Outside of work, Mackie enjoys working out, exploring music, and watching films.